| |

| Alternator

& Charging System Basics |

|

|

(More

tech articles on the Tech, Tests & Installs page HERE)

I

had an electrical fire in the Dodge earlier this season.

For

those of you who’ve never had an electrical fire,

it’s pretty scary. The Dodge was in my shop and

I had just put my new motor in it. I had just started

it up and had it running, getting some heat into it. I

had my back to the car as I was getting my timing light

ready. All of a sudden it just shut off, but I could hear

the fan still running. I turned around and saw plumes

of thick, acrid smoke billowing from the trunk, which

thankfully had been open. I ran to the back of the car

and found the alternator wire in flames and starting to

ignite the other things I had been storing in the trunk

while the engine had been out of the car. Being that the

car had shut itself off, there was no more energy flowing

through the wire so the fire went out pretty quickly at

that point. Still, this was a wake-up call. What had happened

was my alternator had a dead-short that I was not aware

of, which sent way too much juice through the charge wire

going back to the battery.

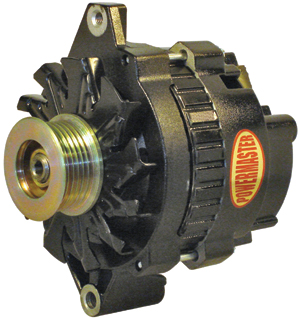

I

spoke with my sponsor Powermaster Performance to learn

more about what might have happened. Powermaster

Performance specializes in starters and high-amp alternators

for a variety of applications including drag racing. According

to Brady Basner of Powermaster, one of

the problems I had in addition to the dead-short was the

size of the wire from the alternator to the battery; it

was a 10 gauge. “The thing I always tell people

is to look at it like plumbing,” said Brady. “From

an alternator's point of view, it needs a clear path to

the battery to charge properly, and a 10 gauge wire to

the back of the car is extremely small. This will create

a great deal of resistance (heat) in the wiring.”

Too small of a charge wire will also result in a loss

of voltage. Brady also informed me that they could repair

my alternator even though it was not a Powermaster unit.

They can fix up any starter or alternator regardless of

manufacture.

So

now I’ll be starting from scratch, rewiring the

Dodge* and installing new components.

How to begin? By doing some research. There’s an

excellent resource in the Tech section of Powermaster’s

website entitled “How

To Choose A Racing Alternator." It details

step-by-step the right way to choose and set-up the correct

charging system for any application. Visit the page; it's

great info. (*Note:

see the rewiring job from start to finish HERE). So

now I’ll be starting from scratch, rewiring the

Dodge* and installing new components.

How to begin? By doing some research. There’s an

excellent resource in the Tech section of Powermaster’s

website entitled “How

To Choose A Racing Alternator." It details

step-by-step the right way to choose and set-up the correct

charging system for any application. Visit the page; it's

great info. (*Note:

see the rewiring job from start to finish HERE).

The

challenge facing any charging system in a race car is

that today's cars have more electrical demand than ever

before. As a result, many of us run high-amp alternators

but neglect to run a larger gauge charge wire to handle

the higher amp loads. This was one of my mistakes. Furthermore,

the pulley ratio has to be correct in order to keep the

alternator charging at various speeds but without over-spinning

it (the maximum RPM for an alternator is 18,000).

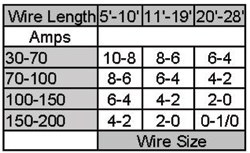

The

first thing to do is make a list of all of the components

of your electrical system: ignition, fans, lights, water

pump, fuel pump, and so on.

Then find the amperage draw for each component,

and check with the manufacturers if need be. Total up

the amps to get the amperage draw for the vehicle, and

figure out the total length of charging wire you’ll

need to get from the alternator to the battery. Now you

can determine the size of the charging wire you’ll

need in order for it to safely handle the draw over the

distance. The

first thing to do is make a list of all of the components

of your electrical system: ignition, fans, lights, water

pump, fuel pump, and so on.

Then find the amperage draw for each component,

and check with the manufacturers if need be. Total up

the amps to get the amperage draw for the vehicle, and

figure out the total length of charging wire you’ll

need to get from the alternator to the battery. Now you

can determine the size of the charging wire you’ll

need in order for it to safely handle the draw over the

distance.

Tighten

Your Belt

According to Powermaster, the #1 reason for alternator

failure including no output is a slipping belt. This has

become a bigger problem with high-amp alternators because

the higher the amps, the more resistance the alternator

has and it takes more power to turn it. Signs of a slipping

belt include:

-

Little

or no output

-

Discharged

battery

-

Pulley

extremely hot and discolored

-

Rust

on alternator shaft,

-

Belt

dust on alternator fan and housing

-

Belt

sticking to pulley

-

Glazed

or cracked belt

-

Belt

too deep in pulley groove

-

Bearing

noise

So

how can you determine if your belt is tight enough? Place

a socket on the alternator pulley. Using a pull handle

in the socket, pull on the handle clockwise. If the pulley

slips, it’s not tight enough. The belt should be

tight enough that it will try to actually turn the engine. So

how can you determine if your belt is tight enough? Place

a socket on the alternator pulley. Using a pull handle

in the socket, pull on the handle clockwise. If the pulley

slips, it’s not tight enough. The belt should be

tight enough that it will try to actually turn the engine.

Next

for the Dodge

will be a complete re-wiring job. I’ll also be installing

the alternator that Powermaster will rebuild as well as

additional components that Moroso Performance

Products suggested, such as their #74107

Alternator Shutdown Relay Kit, #74102 heavy-duty Battery

Disconnect Switch and #74110 Boots

for the battery disconnect switch. We’re also going

to fuse the charging wire as an extra measure.

Choosing

the right alternator and selecting the proper weight wire

will not only improve the charging system’s performance,

but it will make for a safer system. Going overkill on

safety is always a good idea, especially with electrical

systems.

Sources:

Powermaster Performance

www.PowermasterPerformance.com

Moroso

Performance Products

www.Moroso.com

|

|

|

|

|

|

|

Dragtime

News On Location |

Tech,

Tests & Installs |

Bracket

Racing 101 |

|

|

Visit

the Tech,

Tests & Installs main page. |

Visit

the Bracket

Racing 101 main page.

|

|

|

|

|

|

|

|